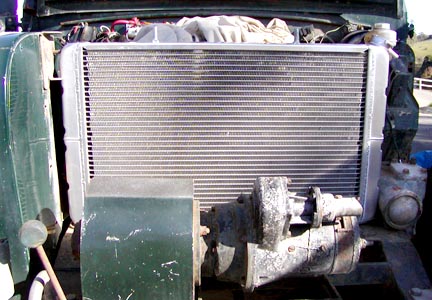

Instead of an SIII radiator that sits behind the front cross member you can use an aluminum cross flow radiator that sits on top of the front cross member, gain more space and more cooling. Gryphon has a stock one that some folks with engine conversions have been using. It does mean cutting down some of the baffling on the radiator bulkhead and coming up with a new horn mounting location.

I am using an electric radiator fan from a 1990's Mercedes V8 sedan. There seems to be one standard size that came with the V8. It is largest fan that will fit vertically behind the grille. It is high quality Bosh & only cost me $40 from my local wrecking yard.The Mercedes mounting struts got reused in my application. The fan sits in a shallow inverted U channel bolted to the front cross member.

When it came time to get radiator hoses I bought a pair of flexible heater air duct hoses and bent them into the shape and lengths I needed. Then I went browsing at an auto parts store looking for hoses that fit the pattern. In each case I found my needed hose inside the shape of a longer hose. I brought the hoses home and cut out the part that matched my pattern. Your alternative of course is the accordion flex radiator hoses but they do not flow nearly as well as a smooth hose.

Reply With Quote

Reply With Quote