-

Clutch doesn't disengage?

Clutch doesn't disengage?

1972 Series III 2.25 petrol 88". The clutch pedal became "softer" progressively but fairly quickly - over just a day or two. Then I started it in neutral and tried to drive but it wouldn't go into gear at all.

New master and slave cylinders installed, all unions renewed, well bled and no leaks in the circuit. But pedal is still very soft and will not go into gear when the engine is running. Fearing something else very horrible is broken. Is there anything else I can check visually? The throw out bearing and lever are well hidden unless I am looking in the wrong place/way.

Your advice will be much appreciated.

Last edited by rayberne; 02-27-2022 at 10:17 AM.

-

well, you'll get lots of advise here !!

you say the gearbox cross member is in the way of linkage? and you mention slave ''well bled''. I'll assume you have the hydrostatic clutch in which case I"d suspect the actuating arm is missing its' aim point. when you put it into any gear it will be in gear right?? I mean, if you crank the starter the truck would move? if the engine were running it'd grind a gear right? (eliminating a xmission issue))

sometimes it can be difficult to get the all the air out of that line to the slave cylinder,Sometimes i've moved it to a hill to work the last of it out tho it isn't totally necessary. I'd guess

-

continued: the actuating arm is probably out of alignment (assuming the slave works ok)

-

Thanks Jim.

The trans moves easily into and out of gear as expected when the engine is off. The car starts fine with the gearbox in neutral, car lurches if attempting to start while in gear because the clutch is not disengaging the trans.

Hydraulics were reverse bled until all air was purged. Actuating rod is firmly retained by the clip opposite the slave and is properly located in the slave.

Last edited by rayberne; 02-28-2022 at 10:49 AM.

-

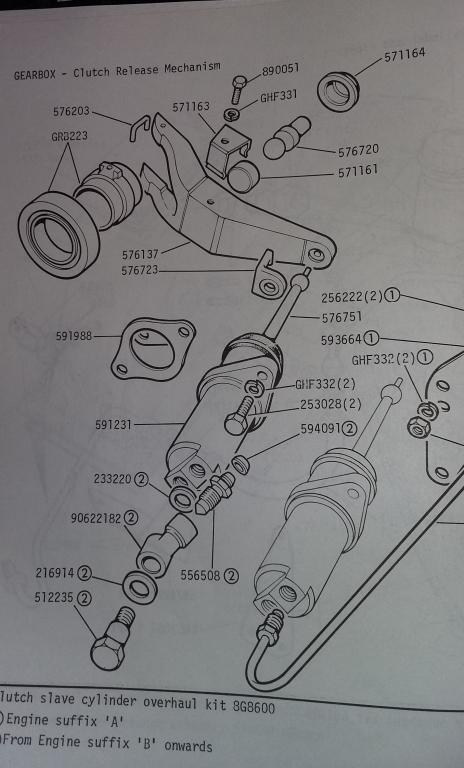

Its possible the lever 576137 inside the clutch housing has worn . It pivots on a ball and can wear through . If you are getting full throw of the slave cylinder , it may not be pushing on the clutch release bearing.

-

Is anyone aware of another way to verify whether the slave cylinder rod and bearing lever are OK?

Thanks.

Last edited by rayberne; 02-28-2022 at 10:51 AM.

-

you might visually observe action via the water drain hole with a 'probe' (visual camera sees thru holes"_ ........ what i've done is just remove the slave cylinder and feel around with the shaft and make sure it feels right. i guess you can move the shaft/rod with a lever or something and see how it moves, how far etc. but the better thing to do is see how far the slave cylinder actually moves which of course you would have to induce a "load" on it as any air in there will move it anyway. you might be able to use longer bolts and leave a gap between the bell housing and the cylinder, enough to see in there with a flash light, mark the shaft then actuate the cylinder and possibly measure the movement, ((accounting for the gap))) but all i've ever had to do is use half a can of fluid (all over the place)) and b. endeavor to move that shaft around and make damn sure yo're convinced it's in the right spot. the newer clip that holds that shaft may be a little flaky but you sure ought to be able to tell if it is 'in the hole' or not.

my biggest issue on that was just getting the air out because it's never been as easy as the brakes for sure. put a bleed tube on the vent to a jar and pump hell out of that cylinder!! you should be able to tell which is the problem.. air or she shaft not seated.

-

don't give up rayberne, if all you've done is replace gaskets etc. (no rods, cylinders etc) then in my opinion it's 90% chance of air still in that line. It isn't as easy as you read to get out. in fact the easier thing to do is reach the bolts to get the cylinder out !!!

-

You could try removing the "shim" or metal gasket (not sure what it does) as it will give your rod more stroke on the fork.

-

There is a short piece of braided rubber hose (RH) that can go soft.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Reply With Quote

Reply With Quote