If the Landy has been in a garage since then I would doubt the clutch is stuck to the flywheel. Especially since, by your pictures of the withdrawal sleeve, it doesn't seem like the withdrawal sleeve is pushing in the pressure plate fingers.

clutch not engaging?

Collapse

X

-

Mat,

I just looked through your old posts to get a better idea of what's going on with your rig. Wow! You've been at this restoration since 2007. I bet it's gonna be awesome! Must be a real let down to have come this far to have the clutch giving you issues especially when you were all ready to pull it out of the garage for the first time in, literally, years. Congratulations though on getting it this far along in your restoration!

Post pics of the finished rig when you get this little issue sorted.Walker

1968 Series IIA-"Ronnie"

88" SW, 2.25L Petrol, LHDComment

-

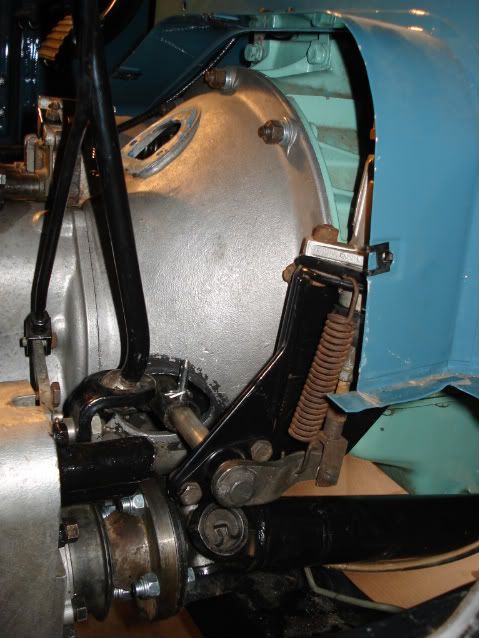

Here is the latest picture. If only it would drive...Mat,

I just looked through your old posts to get a better idea of what's going on with your rig. Wow! You've been at this restoration since 2007. I bet it's gonna be awesome! Must be a real let down to have come this far to have the clutch giving you issues especially when you were all ready to pull it out of the garage for the first time in, literally, years. Congratulations though on getting it this far along in your restoration!

Post pics of the finished rig when you get this little issue sorted.

Comment

-

If your throw out isn't making it to the pressure plate fingers then perhaps you need to take a look at the cross shaft assembly. The pins and the sleeve might be put together incorrectly or may just have too much slop. There is a small spherical bearing that can wear out causing the shaft not to rotate enough also.Jason

"Clubs are for Chumps" Club presidentComment

-

I went and pulled out the old clutch pressure plate and they all look different. The truck currently has a series IIA trans in it.

All three look different:

original set up that was in the II when i bought the truck in later 2006

clutch clutch pressure plate out of series IIA that came with the IIA trans and motor:

the one in now is a "ap borg & beck clutch parts" (thats what is says on the box) and came with the Canadian military rebuilt motor.

sorry for all the pictures but i think they say a lot more then i can tell yall... this is my first rebuild ever and i really appreciate all the help and advise.Comment

-

The more pics the better . One pic says a thousand words.

. One pic says a thousand words.

There are some things about your slave cylinder fitted to the vehicle. It is a Late type hydrostatic setup you don't need the return spring fit to the cranked operating rod you should remove it. There looks to be a spacer between the slave cylinder and the support bracket there shouldn't be one. The support bracket for the slave cylinder should be straight up and down where yours is pitched to the front of the vehicle. Why?Walker

1968 Series IIA-"Ronnie"

88" SW, 2.25L Petrol, LHDComment

-

I went and looked at my setup for the support bracket for the slave cylinder and I was wrong it is pitched somewaht to the front of the vehicle. As long as yours is bolted flat to the bell housing it should be fine. Sorry about that. I'm going to bet removing that spacer is gonna give you the distance you need to get the withdrawal sleeve to engage the pressure plate.Walker

1968 Series IIA-"Ronnie"

88" SW, 2.25L Petrol, LHDComment

-

Mat

I think the spacer Nium was referring to was the black one in between the slave cylinder and the mounting bracket. I know that I have seen that spacer before, but I dont believe it goes with the bracket you have mounted on your truck. Its hard for me to remember which has which and I am not in my shop to look at a parts book.1965 109 2door hardtop (restored years ago)

1971 88 (restored and as new)

1967 88 (the next project)Comment

-

Exactly as Bertha said. Look at your picture

Remove the spring attached to the slave cylinder arm. Remove the black spacer (looks to be about 1/4" in thickness) between the slave cylinder and the bracket the slave cylinder is attached to. The spring is for the early style slave cylinder not the hydrostatic setup you have, don't use it. I don't know what the spacer is for I've never seen one for a hydrostatic slave cylinder.

The new pressure plates DO NOT use the center spacer piece like the old ones. DO NOT try to fit one to your new pressure plate.

The hydrostatic slave is self adjusting. The pressure plate itself is all that is needed to push the slave cylinder back. That is why you need to remove that big rusty spring in the picture.Walker

1968 Series IIA-"Ronnie"

88" SW, 2.25L Petrol, LHDComment

-

Here's a picture of a slave cylinder to show you that the spring and spacer are absent. The PO for this pic had welded a bit of rod to the slave push rod so the push rod is longer then it's suppose to be and the owner whom took the pic (not my rig) was bleeding the slave so you can see a tube full of fluid hanging down in front of the bell housing.

Walker

Walker

1968 Series IIA-"Ronnie"

88" SW, 2.25L Petrol, LHDComment

-

The rover i took the trans out of had the same pressure plate and spring on it (out of a series IIA)i some how added the spacer to the slave so i will remove that. the new pressure plate is identical to the old one other then not having that spacer in are you positive that i do not need it? sorry for questioning but i really want to get this right.Exactly as Bertha said. Look at your picture

Remove the spring attached to the slave cylinder arm. Remove the black spacer (looks to be about 1/4" in thickness) between the slave cylinder and the bracket the slave cylinder is attached to. The spring is for the early style slave cylinder not the hydrostatic setup you have, don't use it. I don't know what the spacer is for I've never seen one for a hydrostatic slave cylinder.

The new pressure plates DO NOT use the center spacer piece like the old ones. DO NOT try to fit one to your new pressure plate.

Thanks for the advice,

-MatComment

-

the mystery will be solved......

MatThe rover i took the trans out of had the same pressure plate and spring on it (out of a series IIA)i some how added the spacer to the slave so i will remove that. the new pressure plate is identical to the old one other then not having that spacer in are you positive that i do not need it? sorry for questioning but i really want to get this right.

Thanks for the advice,

-Mat

Here is the story(now that I am back in my shop I am thinking a lot clearer)

There are 2 different setups depending on which clutch you go with 9" or 9.5". It appears your truck originally had a 9.5 clutch in it(hence the spacer you were refering to on the pressure plate which is non removable) The clutch you currently have on your truck appears to be a 9" which does not require the spacer that Nium was referring to. Soooo, your 2 options are refit the 9.5 clutch or remove the spacer under your slave cylinder. You can also remove the spring on the side of your slave cyl. This should fix your problem.1965 109 2door hardtop (restored years ago)

1971 88 (restored and as new)

1967 88 (the next project)Comment

Comment