Engine to chassis ground

Collapse

X

-

Did it ever run? Did you replace the points?

If the points aren't installed correctly they will short to ground. There's an insulator that has to be fitted correctly.Tom Rowe

Four wheel drive allows you to get stuck

in places even more inaccessible.

62 88 reg

67 NADA x2

74 Air Portable - The Antichrist (tag 6A666)

95 D1 - R380

95 D90 - R380

97 D1 - ZFComment

-

It has never ran since I bought it 10 years ago. I'm in the middle of a frame off restoration, and am at the point of hooking things up to start it. It is not ready to drive yet though, but I just wanted to see if I could get it started. The distributor is the original, but new cap, rotor, points and condenser. Also new coil, leads and spark plugs. I would say that it hasn't run in 20 years.Doug

61 Series II 109 SW

95 RR County LWB

06 Range Rover

98 Discovery LEComment

-

It has been at least 20 years so century Gary Foster drove that 109. Double check the points. I don't remember what distributor that had on it but I once assembled mine and put the insulator in the wrong spot as Tom mentioned and it was frustrating. Relatively easy to diagnose with a test light though. Also don't forget to turn your ignition off when done. You can melt the points otherwise. I did that once and got stranded in the cemetery over in Edmeston... had to make some from scratch to get home. Fun times.Comment

-

Thanks Matt. It has the original 25D distributor in it, but the points, condensor, cap and rotor are new. I'm getting 12V at the point contact with the points open. It's probably something simple, I just don't have enough experience to see it.Doug

61 Series II 109 SW

95 RR County LWB

06 Range Rover

98 Discovery LEComment

-

I'm confident it is something simple. Get a test light and go from there. Some tips here:http://www.minimania.com/Troubleshooting_Lucas_PointsComment

-

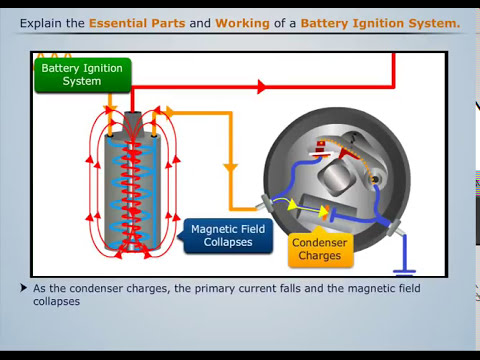

This is a fairly simple system. To maintain the system, you really should know how it works and what each component's role in the system is.

This is one of the best and most thorough explanations of the theory of operation of a points-type ignition system I could find on YouTube:

Once you understand how the system operates, you'll be able to test your non-functioning system in a logical manner till you find the problem. You'll want to be able to test to see if there is an electrical path between certain things in the system and you'll need to be able to test for voltage at certain places in the system.

For example, you've got to realize that with the points OPEN, one contact (the one that is NOT connected to the capacitor/condenser) will still be grounded (there will be an electrical path to the metal engine) when the points are open, while the other contact (the one that's connected to the capacitor) MUST NOT go to ground (must NOT have an electrical path to the metal on the engine), otherwise the circuit will never be broken, even with the points wide open because the electricity will still have a path to ground, causing the system NOT to work.Last edited by SafeAirOne; 08-11-2015, 05:03 PM.--Mark

1973 SIII 109 RHD 2.5NA Diesel

0-54mph in just under 11.5 minutes

(9.7 minutes now that she's a 3-door).Comment

-

At this point, I don't care if I come across as a moron with regards to this subject. I went on the link that Matt(Yorker) listed and followed the tests, and I can get a spark on a test spark plug through test 4. I have some seemingly stupid questions.

1. I'm getting 12v on the condenser side of the points with the points open and closed. Is this supposed to happen?

2. How does the rotor fit on? Mine seems to spin freely. How is it supposed to be at the ignition terminal in the cap when the points are open. Do you get the points to open and make sure that the rotor arm is in line with one of the contacts in the cap?

I'm really not stupid.Doug

61 Series II 109 SW

95 RR County LWB

06 Range Rover

98 Discovery LEComment

-

Yes, the condenser side of the points should have 12v whenever the ignition switch is on. The other side of the points should only have 12v when the points are closed.

Generally, that takes care of itself. The rotor only fits on the distributor shaft one way, with the flat in the hole in the rotor matching up with the flat on the shaft. There may be a small bit of play/slop in the distributor shaft, but that shouldn't matter.2. How does the rotor fit on? Mine seems to spin freely. How is it supposed to be at the ignition terminal in the cap when the points are open. Do you get the points to open and make sure that the rotor arm is in line with one of the contacts in the cap?

The theoretical way it should work is that the points open up as the contact on the rotor passes one of the contacts on the underside of the distributor cap so that pulse of high voltage that occurs when the points open up will immediately have somewhere to go.

You'll be fine--It's just a matter of getting used to how the thing works. You'll be an ignition system expert by the time you get this engine running.I'm really not stupid.

That flow chart that Yorker linked to is pretty good.

Are you getting spark at step 4, where you have a grounded spark plug connected to the center coil wire (the fat one) and you make/break the primary circuit manually with the ignition switch on, or just UP TO (but not including) step 4?

PS: Most painless way to ground the spark plug is to clamp one of the leads from a set of jumper cables to the spark plug threaded body and the other end of the same jumper cable to a ground or the - battery terminal. That'll save you from trying to hold it next to the engine to ground it (and you won't be zapping yourself).--Mark

1973 SIII 109 RHD 2.5NA Diesel

0-54mph in just under 11.5 minutes

(9.7 minutes now that she's a 3-door).Comment

-

You were getting 12v on the condenser side of the points with the points open before. Now you're not getting 12v there when the points are closed?

1) Is the ignition on?

2) Are you probing with your meter on the 20v scale, with the red lead on the points contact and the black probe on a good bare metal ground on the engine?--Mark

1973 SIII 109 RHD 2.5NA Diesel

0-54mph in just under 11.5 minutes

(9.7 minutes now that she's a 3-door).Comment

-

Just re-read your last post...

If you ARE getting spark in step 4 when you manually break the circuit and you're not getting 12v on the NON-condenser side of the points when the points are closed, then, presuming the ignition switch is on, electricity is, for whatever reason, not making it across the contact points when the contacts are touching each other (closed).

I would:

1) Make sure the ignition switch is on and re-test if it was off.

2) Make sure the little cam follower is completely off the little lobes on the distributor shaft and that the contact points are actually touching when the points are closed. Even a little open won't cut it in this position. (Ignition off when you're doing this!) Retest.

3) With the ignition off, take a tiny file or some sandpaper and clean off both contact points so that there is nothing inhibiting the flow of electricity from one contact to the other when they are fully closed (physically touching each other). [EDIT:] Oh, hey--This is step 5 of the flow chart test procedure!--Mark

1973 SIII 109 RHD 2.5NA Diesel

0-54mph in just under 11.5 minutes

(9.7 minutes now that she's a 3-door).Comment

-

Any luck?Comment

Comment